TotalEnergies entwickelt seit mehr als sechzig Jahren innovative Hochleistungsschmierstoffe.

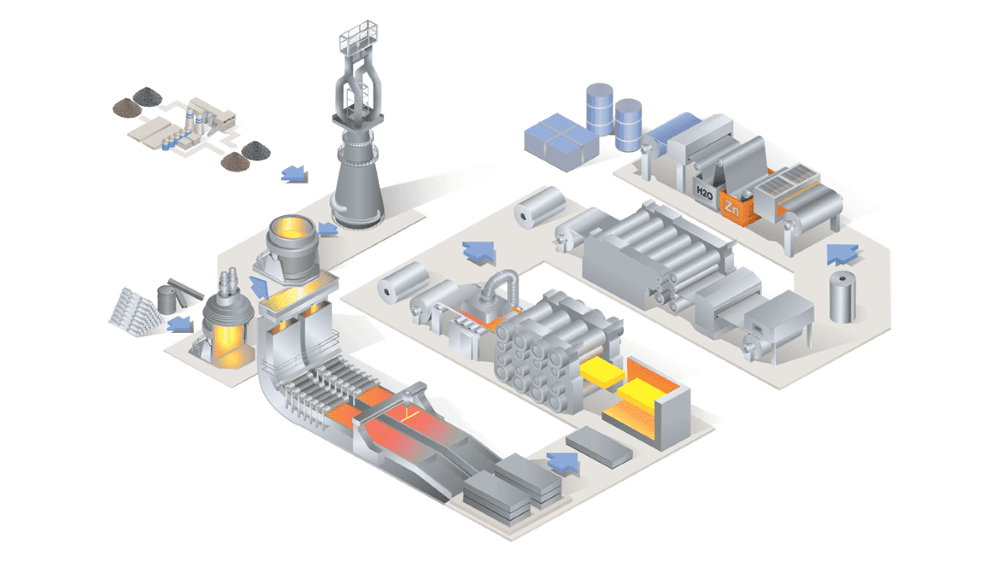

In einem hart umkämpften Markt, wie der Stahlindustrie, muss jede Einsparung zur Senkung der Betriebs- und Wartungskosten, sowie zur Verbesserung der Produktivität, berücksichtigt werden. Wir bieten verbesserte Lösungen für Ihre Anlagen und Prozesse und sorgen für erhöhte Zuverlässigkeit bei den eingesetzten Schmierstoffen. Unser Angebot an hochwertigen Prozessölen zum Walzen bezieht auch die besten TCO (Total Cost of Ownership) mit ein.Wir verpflichten uns, gute technische Produkte und Dienstleistungen anzubieten, die sich auf Sicherheit, Qualität, Umweltschutz konzentrieren und eine Technologie zur CO2-Reduzierung bieten.

Unsere Schmierstoffe für die Stahlindustrie

-

0+Jahre Erfahrung in der Stahlindustrie

-

0+Länder

TotalEnergies bietet Hochleistungsöle und -fette zur Optimierung des Lebenszyklus wichtiger Anlagen und kritischer Ausrüstungen bei gleichzeitiger Minimierung von Ausfallzeiten und Wartungskosten.

Wir verfügen über mehr als ein halbes Jahrhundert an Fachwissen und Erfahrung, um alle Betriebsbedingungen im Zusammenhang mit der Stahlbearbeitung zu bewältigen und zu entwickeln:

- Getriebeöle (Carter-Reihe)

- Hochleistungs-Kalziumsulfonat-Komplexfette speziell für Stahlindustrie (Ceran-Reihe)

- Schwerentflammbare Hydraulikflüssigkeiten (Hydransafe-Reihe)

- Formtrennmittel für hohe Temperaturen (Ironcast-Reihe)

Ceran – die besonderen Fette für Ihre Maschinen

Unsere Ceran Fette bieten Ihren Industrieanlagen durch die optimierte Schmierung einen höheren Schutz und eine lange Lebensdauer für Ihre Maschinen und senken somit Ihre Wartungskosten. Mit der Verwendung von Ceran Schmierstoffen, die unbedenklich und umweltfreundlich sind, fördern Sie den Gesundheitsschutz und die Sicherheit Ihrer Mitarbeiter und schützen die Umwelt.

Seit 20 Jahren sind wir erfolgreich auf dem Gebiet der Kalziumsulfonat-Komplexfette aktiv und bringen mit der mittlerweile 5. Ceran Generation eine Produktreihe auf den Markt, die den Ansprüchen von heute und morgen gerecht wird.

Verglichen mit den Standardfetten verfügt die Ceran Reihe über eine besondere Seifenstruktur, bestehend aus Fasern und Mizellen. Diese einzigartige strukturelle Anordnung bietet herausragende Fetteigenschaften, insbesondere im Hinblick auf:

- die mechanische Stabilität

- den Korrosionsschutz

- Wasserbeständigkeit

Mit Ceran Schmierstoffen Umweltschutz fördern

Die Ceran Fette enthalten keine Schwermetalle und keine Bestandteile, die eine Gefahr für die Gesundheit und die Umwelt darstellen. In der Stahlindustrie bieten die Ceran Fette die „klassenbeste” Leistung im Hinblick auf die Beständigkeit gegenüber Wasserauswaschungen.

Das Prozesswasser ist weniger durch Schmierfettverluste kontaminiert, wodurch unsere Ceran Reihe Einsparungen im Hinblick auf Wasseraufbereitungsadditive und Filterreinigung ermöglicht. Das wirkt sich zusätzlich positiv auf die Umwelt aus.

Da die Ceran Fette einen sehr umfangreichen Anwendungsbereich abdecken, können Sie Ihre Schmier-Fettbestände reduzieren. Zusätzlich bietet der neue Verdicker einen verbesserten Korrosionsschutz und liefert maximalen Langzeitschutz für Ihre Ausrüstung. Mit der Verwendung von Ceran Fetten lassen sich außerdem Nachschmiermengen reduzieren und die Schmierintervalle verlängern. Das führt langfristig zu Einsparungen.

Die Vorteile der Ceran-Fette auf einen Blick:

Unsere Warmwalzöle für die Stahlindustrie: Rollshield

Die Rollshield-Reihe ist ein Hochleistungs-Warmwalzöl zur Produktion von warmgewalztem Flachbandstahl. Es handelt sich um ein Warmwalzöl auf Esterbasis mit sorgfältig ausgewählten EP- und AW-Additiven. Diese wurden entwickelt, um einen guten Schmierfilm zu erreichen, die Walzkräfte zu verringern und die Lebensdauer der Arbeitswalze zu verlängern. Die Rollshield-Produkte sind mit einer Vielzahl von Industriewässern unterschiedlicher Qualität kompatibel.

Unsere Kaltwalzöle für die Stahlindustrie: Rolkleen

Die Rolkleen-Reihe ist ein halbsynthetischer Stahlkaltwalzschmierstoff, der entwickelt wurde, um saubere Bänder zu produzieren und stabile Betriebsbedingungen bei geringem Verbrauch zu gewährleisten. Dieser Schmierstoff kann auch bei der Kommissionierung eingesetzt werden, inklusive Elektrostatik.